Ultrasonic Cleaning

Ultrasonic cleaning machines utilize high-frequency sound waves to create microscopic bubbles in a cleaning solution. This process, known as cavitation, effectively removes contaminants from a variety of surfaces, making these machines essential in numerous industries, including automotive, medical, and electronics. The efficiency of ultrasonic cleaning can achieve up to 99% removal of dirt, grease, and other residues, depending on the application and cleaning solution used.

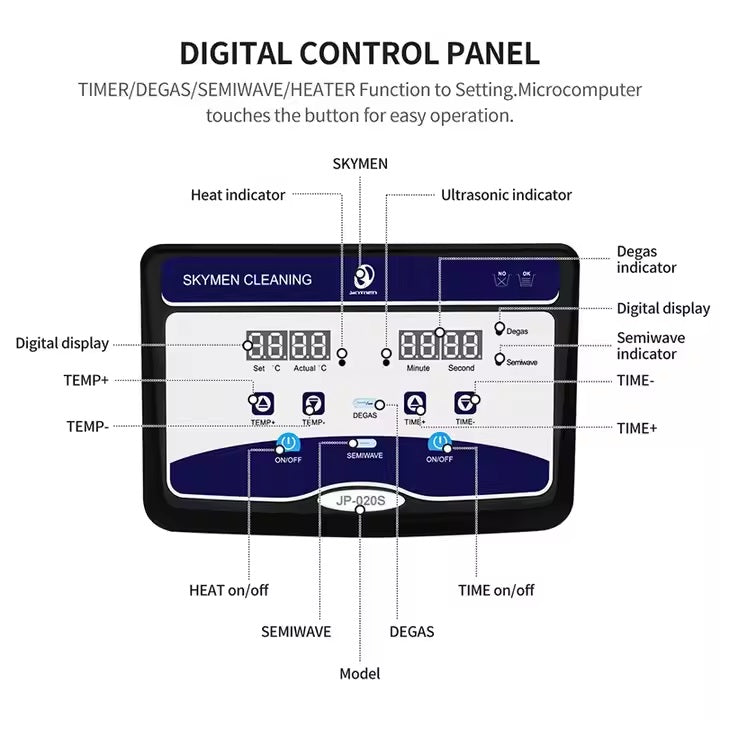

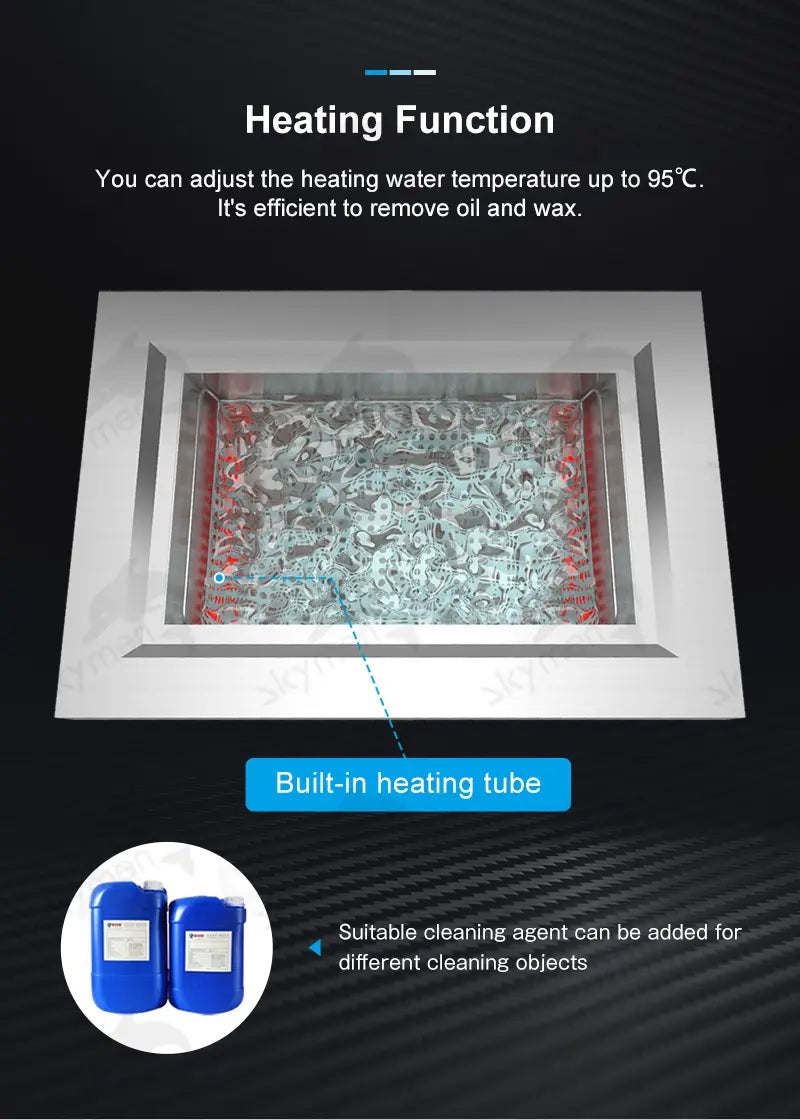

One of the primary features of ultrasonic cleaning machines is their ability to clean intricate parts and components that traditional cleaning methods may not reach. The ultrasonic waves penetrate small crevices and complex geometries, ensuring a thorough clean. Additionally, many models come equipped with adjustable frequency settings, allowing users to tailor the cleaning process to the specific material and level of contamination. For instance, a frequency range of 20 kHz to 40 kHz is commonly used for general cleaning, while higher frequencies are suitable for delicate items. All our machines operate on a 40 kHz frequency.

In terms of warranty, ultrasonic cleaning machines typically come with a manufacturer’s warranty that covers defects in materials and workmanship. We offer a 1 year warranty with an additional year optional.

Services associated with ultrasonic cleaning machines often include installation, training, and maintenance. Proper installation is crucial for optimal performance, as improper setup can lead to inefficiencies. Training services ensure that operators understand the machine's functionality and best practices for achieving the desired cleaning results. Regular maintenance is essential to prolong the lifespan of the equipment and maintain its cleaning efficacy. This may involve routine checks of the ultrasonic transducers, cleaning solution, and overall machine condition.

Spare parts for ultrasonic cleaning machines are readily available and play a significant role in maintaining the equipment's performance. Common spare parts include ultrasonic transducers, heating elements, and tanks. It is important to source these parts from reputable suppliers to ensure compatibility and quality. Regular replacement of worn or damaged components can prevent operational downtime and enhance the machine's cleaning capabilities.

In conclusion, ultrasonic cleaning machines represent a sophisticated solution for achieving high levels of cleanliness across various applications. Their advanced technology, combined with comprehensive warranty options, professional services, and readily available spare parts, makes them a valuable asset for any organization seeking efficient cleaning solutions.